On injection molding machines and extrusion lines with moderate capacities, feeding virgin resin into the machine has traditionally been a simple, gravity-fed process. While effective, it’s not without its limitations, especially for manufacturers who frequently switch raw materials or need precise monitoring of resin consumption. The AccuTrack offers an alternative—a gravimetric screw feeder designed not just for colors or additives but also for any pelletized resin materials, providing better control and flexibility without overhauling the entire feeding system.

AccuTrack feeds natural materials directly into the injection molding machine or extruder to ensure material is fed continuously, while also tracking material usage and simplifying changeovers.

Switching to AccuTrack for resin feeding offers practical advantages:

By integrating AccuTrack into your production line, you get more than just a feeding solution. You gain better control over material consumption, reduce production downtime, and make the entire process more efficient. It’s an upgrade that reflects the direction manufacturing is heading—towards smarter, more automated systems that prioritize precision and reliability.

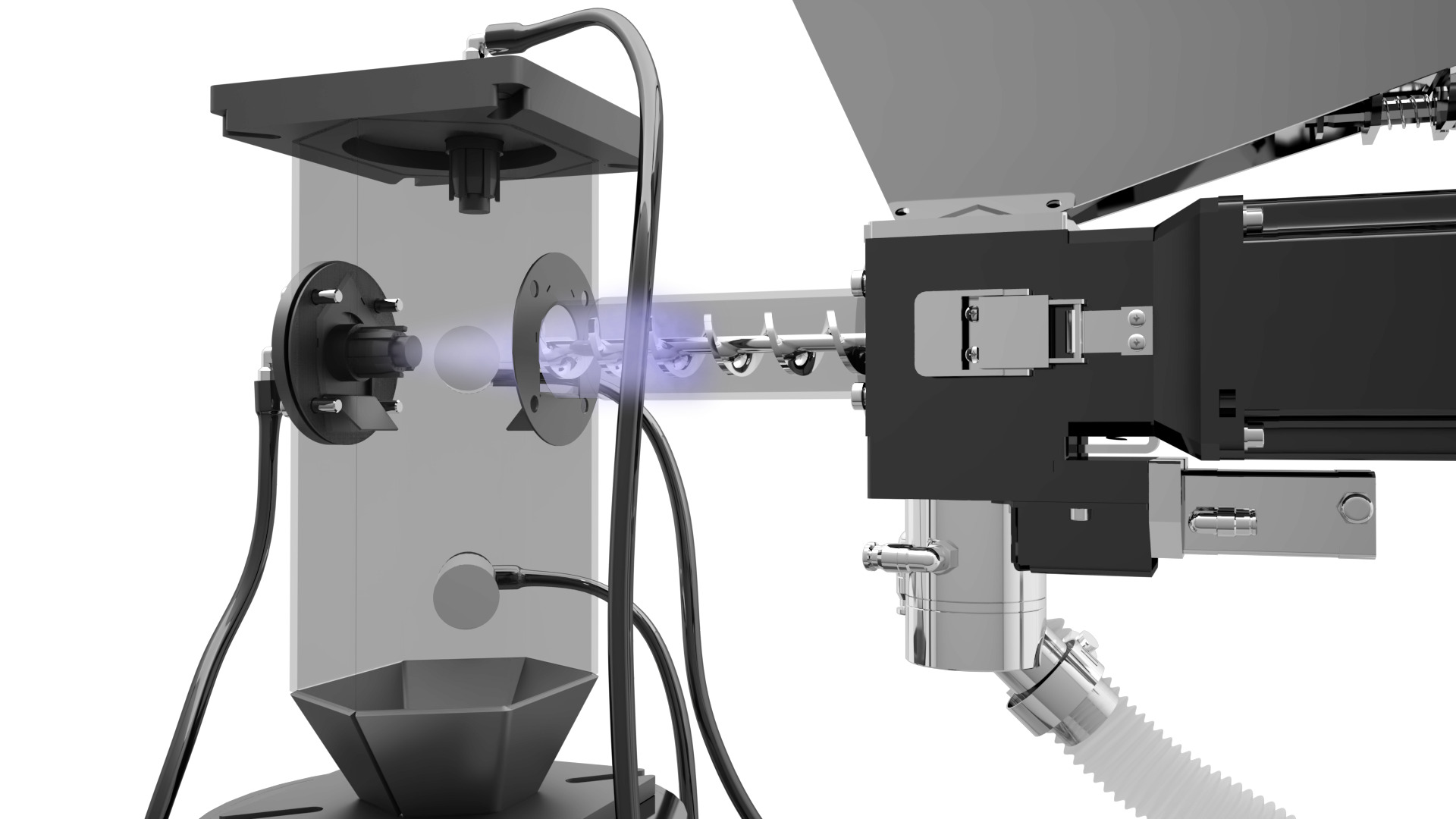

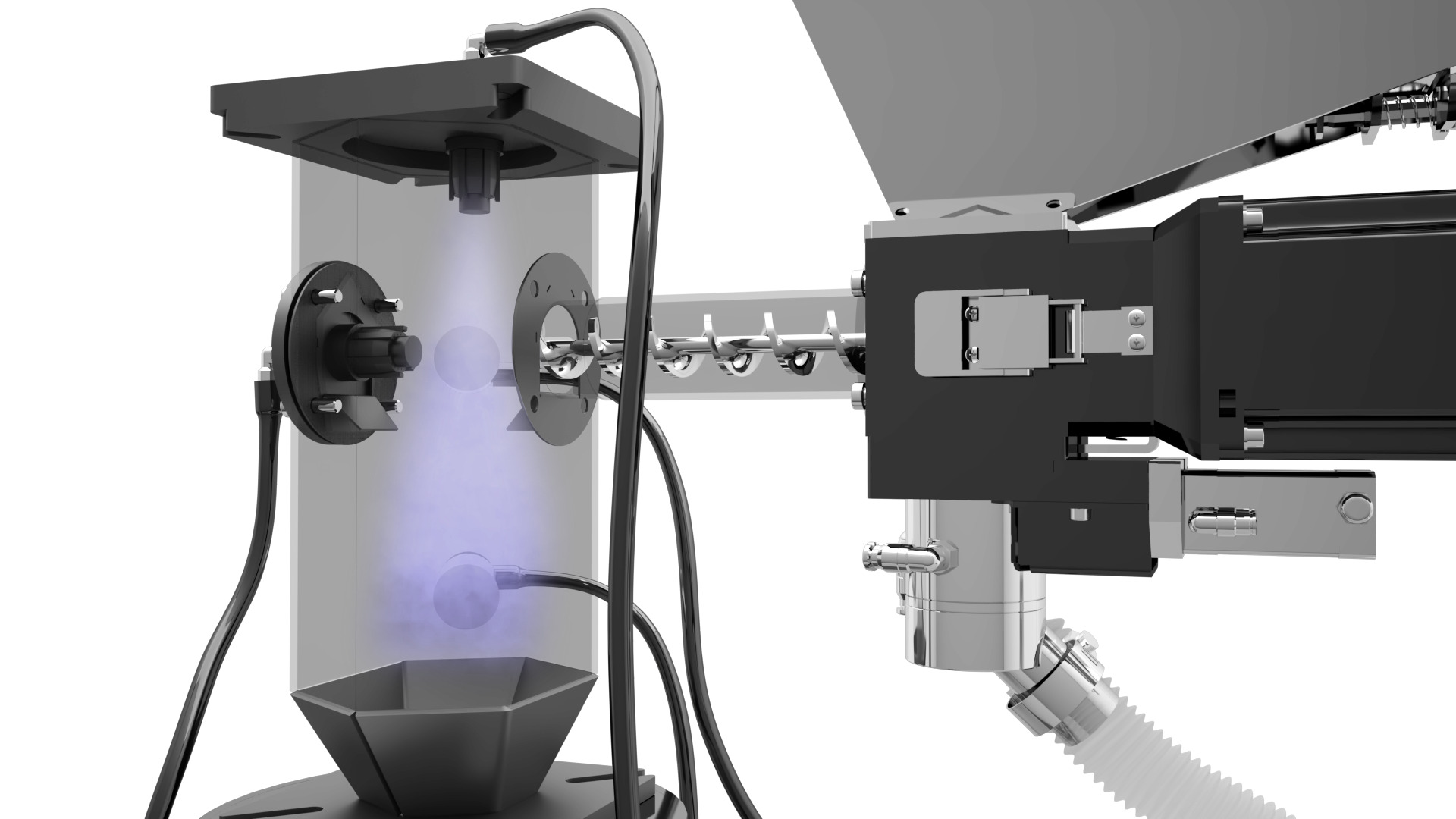

The AccuTrack technology is incorporated into the modified neckpiece that attaches to the extruder for a small footprint solution for accurate resin feeding.

If you’re looking to improve your resin feeding process, the AccuTrack might be the solution you need.

|

|

| Air blow into the feeding screw | Air blow from top |

שוחחו ישירות עם אחד המהנדסים שלנו על-מנת להפחית עלויות ייצור, מלאי וזמן

התקנת ניסיוןCopyright Ampacet Corporation. All Rights Reserved ©