FlowSave is a gravimetric continuous blending system known for its versatility, designed to handle one or more feed channels. In this post, we'll delve into the option that FlowSave offers, beyond merely monitoring material flow. It extends to actively controlling extrusion and even performing layer control in multi-layer systems.

Throughput in a single-screw extruder, often referred to as a "flood-fed" extruder, hinges on two key factors: the motor's rotational speed driving the extruder screw and the bulk density of the raw material being fed into it. A faster rotation augments the extruder's capacity, while variations in raw material density affect the extrusion flow rate.

FlowSave's gravimetric channels usher raw material through a loss-in-weight measuring process. The primary channel operates in freefall feeding, while the additional channels, if present, employ a screw feed mechanism to contribute to the overall flow. These additional flows are determined as percentages of the general flow, contingent upon the raw materials compositions in the production recipe. The FlowSave system continually assesses the throughput to ensure the correct percentage of each material in the recipe. This dynamic adjustment guarantees recipe accuracy throughout production.

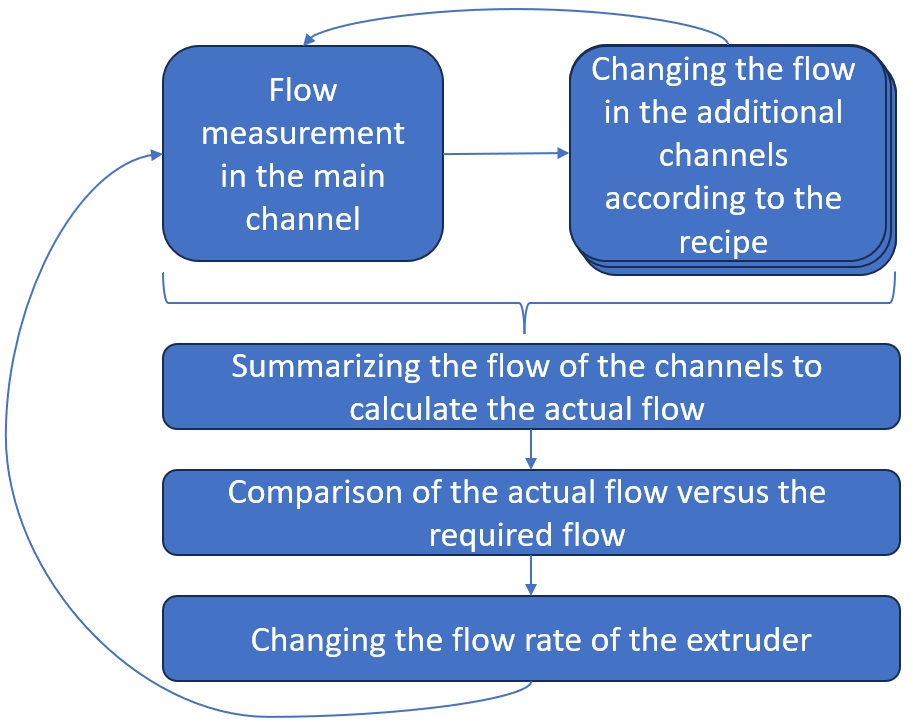

FlowSave introduces the option of extrusion control, a mode where the system receives a predetermined flow rate and actively manages the extruder's actual flow rate in kilograms per hour (kg/h). This control persists throughout the operation. As the bulk density of raw materials can fluctuate during extrusion, FlowSave continuously calculates the total flow rate by amalgamating all channel flows. Any variance between the actual and required flow triggers adjustments in the extruder screw motor speed, aligning the extruder flow with preset parameters.

FlowSave extrusion control

FlowSave extrusion control

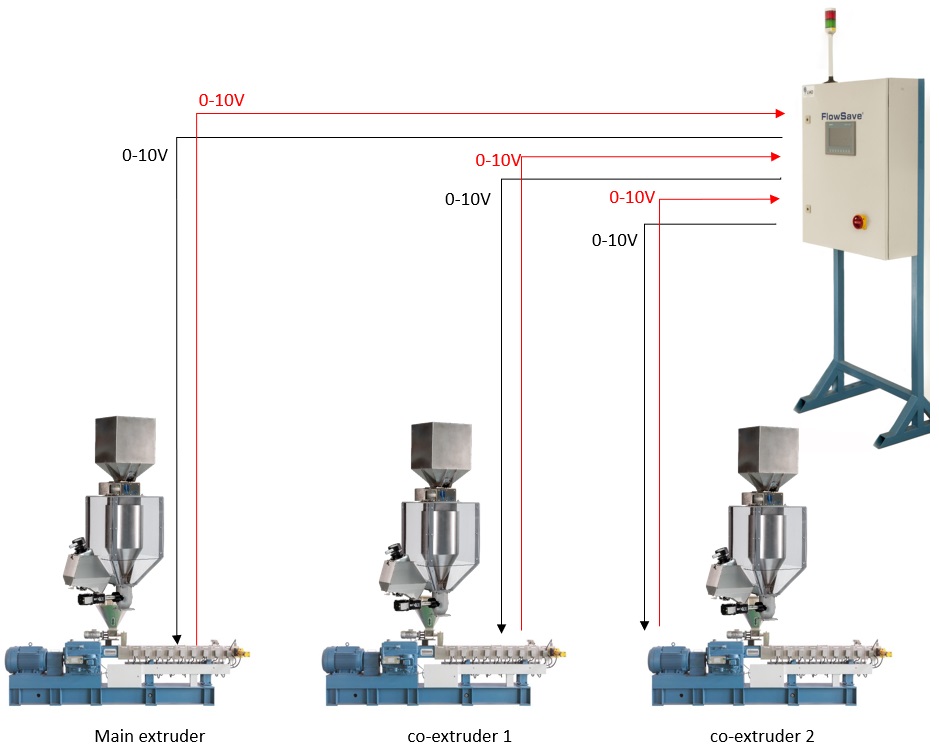

Extrusion control operates via a 0-10VDC analog signal transmitted from the FlowSave control system to the extruder controller. This signal reflects the necessary relative speed of the extruder screw motor to attain the desired flow rate in kg/h. For instance, a 2VDC signal equates to the extruder screw motor operating at 20% of its maximum speed, while 5VDC corresponds to 50%. The FlowSave system continually recalculates the extruder's actual flow rate, adjusting the analog signal's strength to ensure the extruder screw motor operates at the required speed.

The FlowSave system requires an additional 0-10V analog signal from the extruder to facilitate smooth transitions between monitoring-only dosing (without extrusion control) and dosing in extrusion control mode. This signal, relative to the extruder screw motor speed, enables a seamless shift between dosing modes, preventing abrupt changes in motor speed.

FlowSave also empowers layer control in extrusion lines, ensuring a fixed percentage of each layer corresponds to the overall product flow. This process involves FlowSave performing extrusion control by kg/h for each participating extruder based on the defined flow rate and desired layer percentages. FlowSave calculates and maintains the flow of each extruder in kg/h, harmonizing the layer ratios as it performs extrusion control for each unit.

FlowSave's multifaceted capabilities, ranging from precise monitoring to active extrusion control and intricate layer management, underscore its significance in the world of extrusion. By offering control, flexibility, and precision, FlowSave is reshaping the landscape of extrusion processes, promising enhanced efficiency and results in this dynamic industry.

The analog signals between the FlowSave control system and the extruders in layer ratio control

שוחחו ישירות עם אחד המהנדסים שלנו על-מנת להפחית עלויות ייצור, מלאי וזמן

התקנת ניסיוןCopyright Ampacet Corporation. All Rights Reserved ©