ColorSave 1000 offers a special feature – masterbatch dosing during the injection phase. Since not everyone is familiar with this feature, we would like to explain it in this post.

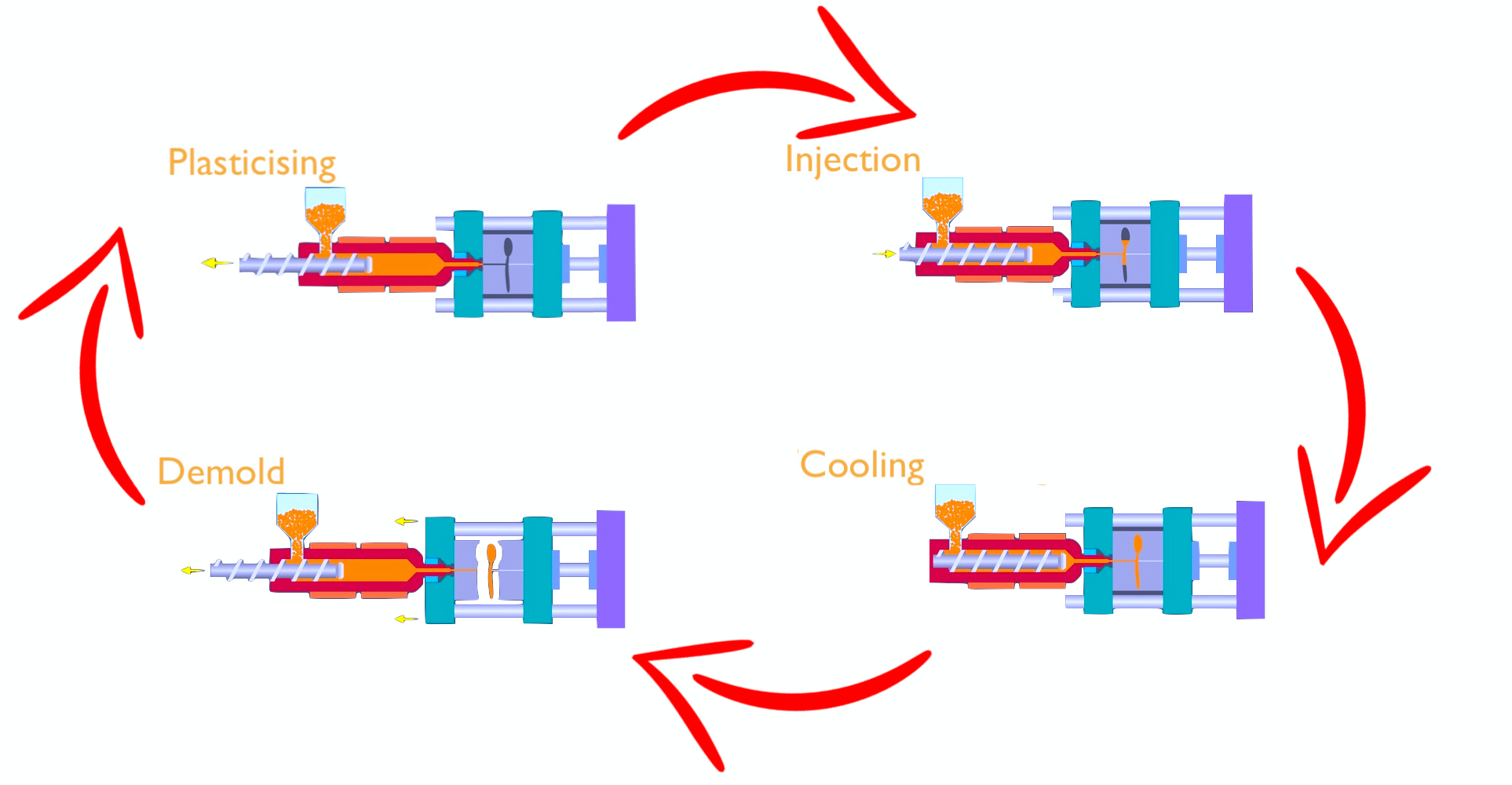

Conventional injection molding cycle comprise of the following 4 phases: plasticizing, injection, cooling and demold. During the plasticizing phase the barrel of the injection molding machine moves backwards and raw material is fed from a hopper into a heated barrel. The second stage is the injection phase where the barrel moves forward and the melted material is injected into the mold. Once the mold is filled, the cooling phase lasts for a predetermined cooling time. Then during the demold phase the mold opened, and the part ejected.

Illustration of the injection molding cycle

As described above, raw material is dosed during the plasticizing phase, therefore masterbatch feeders feed the masterbatch during that time. The reason is to remain with homogeneous material in the injection molding machine, so together with the virgin material from the hopper, masterbatch in the required percentage is fed into the barrel at the same time.

Yet, in some cases it is essential to dose masterbatch also during the injection phase. It may happen when producing very large parts in very large injection molding machines. In those machines, due to their mechanical design, some virgin material is fed into the barrel during the injection phase. In order to keep a good color dispersion inside the injection molding machine some masterbatch should be fed as well.

ColorSave 1000 has a ‘sensor’ cable which is used to interface with the injection molding machine, usually receives only plasticizing signal.

In addition the cable can be connected also to the injection signal from the injection molding machine.

There is nothing else that should be done. Once the ColorSave 1000 receives an injection signal it is automatically adjust itself to dose some of the material during that phase. After a couple of cycles ColorSave 1000 learns the durations of the plasticizing and injection phases divide the masterbatch between them.

Since most of the virgin material is fed during the plasticizing phase, ColorSave 1000 feeds most of the masterbatch during that phase and only small percentage of the masterbatch is fed during the injection phase.

In order to do so, ColorSave 1000 uses a lower motor speed during the injection phase. In addition, the injection phase is shorter than the plasticizing phase. The result of the low speed and the shorter time is that about 90% of masterbatch or additive is added during the plasticizing phase while about 10% is fed during the injection phase.

Converse directamente con nuestros especialistas y encuentre formas de ahorrar en costos, inventario y tiempo.

Calcule su Ahorro© Copyright Ampacet Corporation. All Rights Reserved