Manufacturers across all sectors are under growing pressure to do more with less. In a global environment defined by rising material costs, tighter margins, and increasing customer demands, the focus has shifted from merely producing to producing smarter. This shift is one of the main forces driving the adoption of Industry 4.0 – and at its core lies a simple but powerful concept: connectivity.

A recent Deloitte survey reports that over 70% of manufacturers are investing in digital transformation tools to enhance productivity and efficiency. From ERP systems to IoT devices on the shop floor, the ability to access and act on real-time data is no longer a future ambition-it’s a present necessity.

What many don’t realize is that one of the richest sources of operational data lies in a process as fundamental as dosing. Central dosing systems, when properly equipped, are no longer just feeding raw materials. They are feeding business intelligence.

By monitoring consumption trends, highlighting inefficiencies, and enabling system-wide integration, today’s advanced dosing solutions are helping manufacturers understand how they operate-not just what they produce.

We’ve spent years rethinking what dosing systems can be. More than just a mechanical function, we see them as a bridge between the physical and digital factory. Our PelletSave and BlendSave systems were developed with that philosophy in mind.

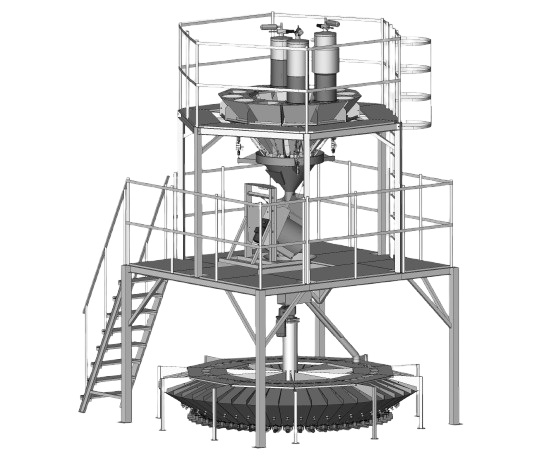

PelletSave

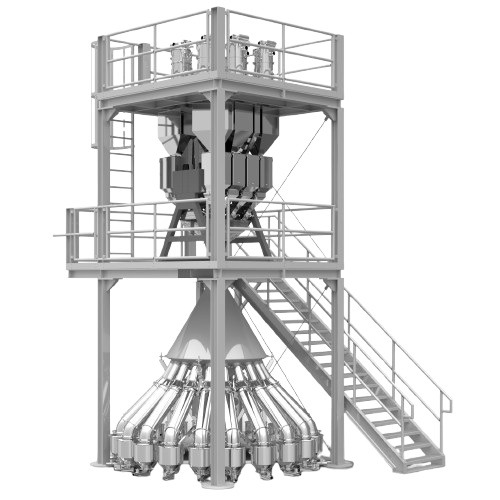

BlendSave

When connected to ERP and MES platforms, LIAD's systems transform into real-time data hubs. They monitor:

This allows plant teams to predict raw material needs, detect inefficient usage patterns, and reduce overconsumption – leading to better inventory planning, fewer interruptions, and more sustainable operations.

As factories become more connected and more intelligent, every system must contribute more than its basic function. At LIAD, we believe dosing is no exception. A well-integrated central dosing system is no longer just an engineering tool but rather a business asset.

By transforming material handling into a stream of usable data, we’re helping manufacturers stay agile, lean, and competitive in a world that demands nothing less.

שוחחו ישירות עם אחד המהנדסים שלנו על-מנת להפחית עלויות ייצור, מלאי וזמן

התקנת ניסיוןCopyright Ampacet Corporation. All Rights Reserved ©