The growing demand for sustainable materials is driving innovation in the recycling industry. One major challenge in processing post-industrial recycled (PIR) plastics is their variable melt flow properties, which are directly influenced by fluctuations in intrinsic viscosity (IV).

The ColorSave 1000 system, equipped with advanced software for additive dosing, offers a solution to this challenge. By using real-time Melt Flow Index (MFI) feedback, ColorSave 1000 ensures precise control over the feeding of flow-enhancing additives, stabilizing the melt flow and producing consistent, high-performing PIR material.

One of the key issues with PIR material is the variability in intrinsic viscosity and melt flow properties. IV, which reflects the molecular weight of the polymer, plays a significant role in determining the material’s flow behavior during processing. PIR plastics often combine materials from different sources, each contributing unique properties such as molecular weight distribution, levels of degradation, and contamination.

This diversity results in unpredictable changes in viscosity, causing fluctuations in melt flow that can negatively impact processing and product quality.

Flow-enhancing additives are a crucial tool for managing this variability. These additives modify the viscosity of the molten material, improving its flow properties and compensating for inconsistencies in IV. However, precise dosing is essential to strike the right balance and achieve the desired properties without compromising the integrity of the recycled material.

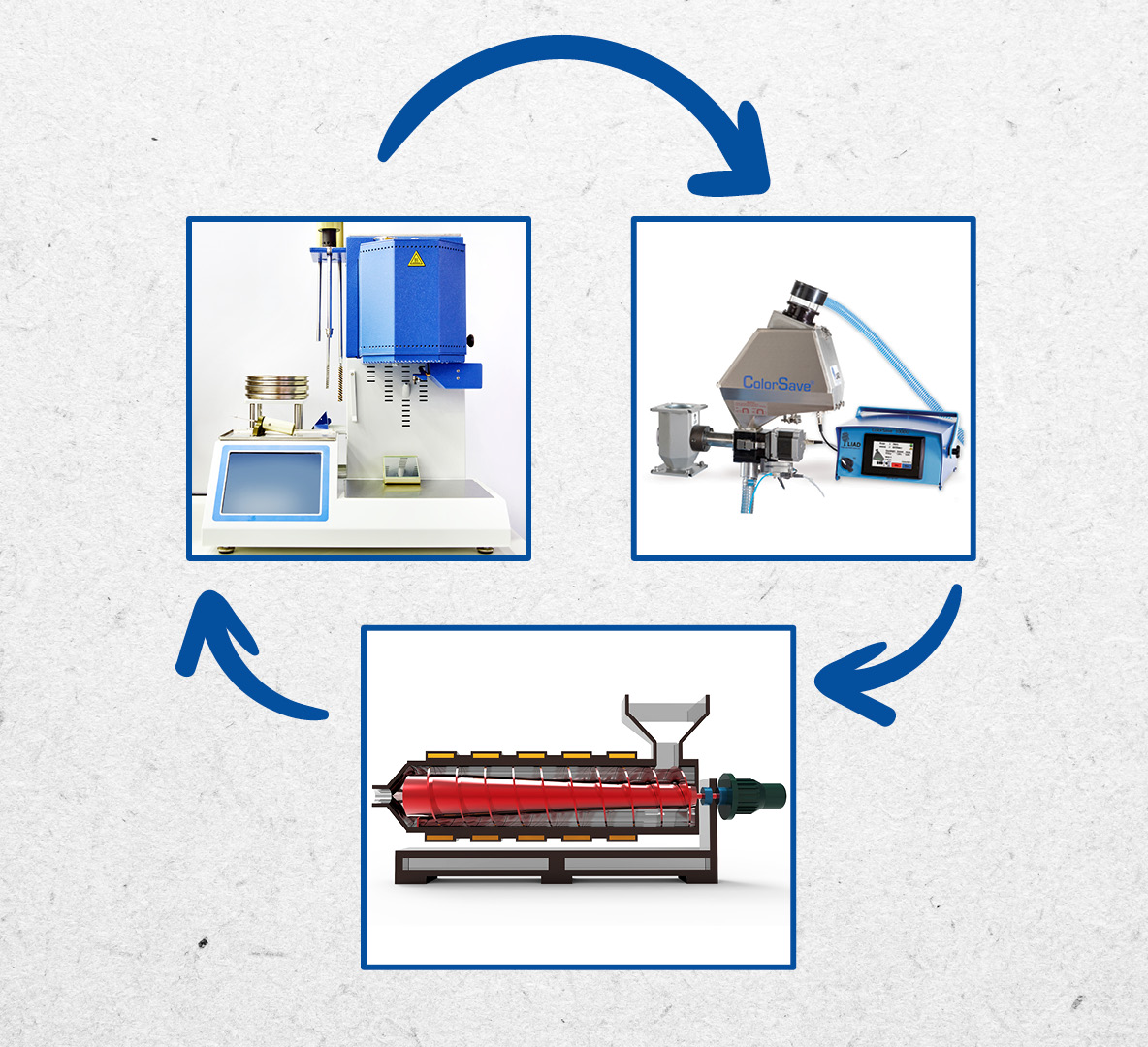

The ColorSave 1000 feeder is using a real-time feedback from an MFI integrated in the extruder to automate dosing adjustments. Here’s how the system works:

By continuously monitoring and adjusting the additive dosage, the ColorSave 1000 ensures that the final PIR granules have consistent melt flow properties, despite variations in IV or the raw input materials.

Flow-enhancing additives and ColorSave 1000’s precision dosing system aren’t just valuable for recyclers—they’re also important for manufacturers who use PIR materials.

For recyclers, controlling intrinsic viscosity and achieving consistent melt flow in PIR granules allows them to supply high-quality recycled materials that meet stringent customer demands. This consistency enhances their reputation, minimizes waste, and improves operational efficiency.

For manufacturers, the benefits are even more pronounced. Variations in melt flow can disrupt production processes, causing downtime, defects, and inefficiencies. PIR materials with stabilized melt flow properties ensure smoother production, reducing the likelihood of defects and increasing throughput.

Moreover, improved melt flow makes PIR materials easier to process, enabling manufacturers to expand their applications. This opens up opportunities for producing high-performance products that require precise and consistent input materials, making PIR plastics a viable alternative to virgin materials in more demanding markets.

This innovation not only improves efficiency and product quality but also supports the broader push for sustainability. As the demand for recycled plastics grows, tools like ColorSave 1000 will play a crucial role in closing the loop on plastic waste and creating a greener, more sustainable future.

Speak directly with our engineers and find ways to reduce cost, inventory and time

Request a Demo© Copyright Ampacet Corporation. All Rights Reserved