Since 2020, the plastic manufacturing industry has witnessed a dramatic shift. Manufacturing floor connectivity is no longer just a “nice-to-have” – it has become the backbone of modern production. With recent surveys indicating that over 62% of manufacturers had already adopted connected technologies by 2023, the market is sending a clear message: isolated machines are a thing of the past.

At LIADSmart, we understand that investing in high-end dosing, mixing, and QC systems is only half the battle. The other half is ensuring those systems can “speak” fluently with the rest of your factory. Our focus is on what matters most to our customers right now: robust, practical, and customized integration with your existing software and controllers.

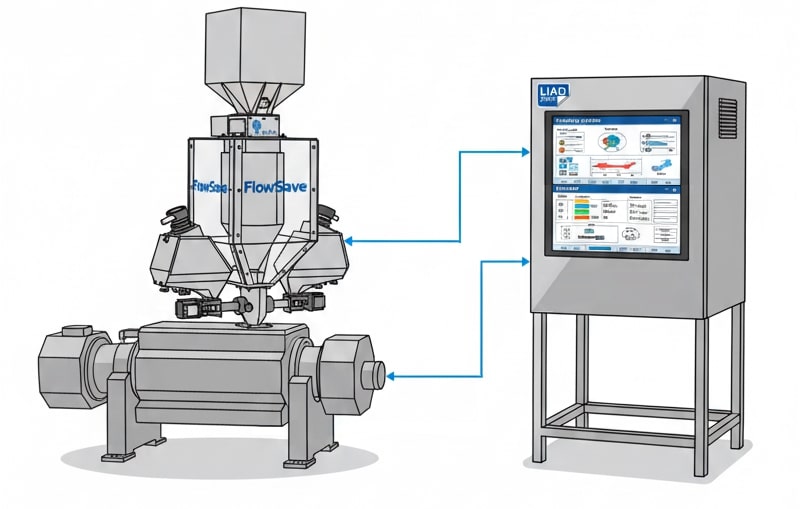

In a typical continuous feeding setup, operators are often overwhelmed by monitors. They have the extruder controller, the feeder screen, and perhaps others. A major request we receive is to consolidate these into a single interface to reduce human error and simplify training.

We have successfully executed projects where we integrated our feeding systems directly into the extruder’s control panel. In a recent collaboration, we worked closely with an extruder manufacturer’s programming team to ensure their screen could fully control our feeders. To achieve this securely, we utilized a PN Coupler (Profinet Coupler). This hardware allowed us to bridge the gap between our network and the extruder’s network, enabling seamless communication while keeping the networks technically separate for security and stability.

The result? The operator inputs all recipes and data solely on the extruder screen, without ever needing to touch our controller. However, flexibility is key. We design these systems so they can operate with or without this connection, ensuring production never stops even if the network goes down.

One integrated screen for controlling both the feeding system and the extruder

One of the distinct advantages of choosing LIADSmart is our agility. We often hear from customers that requesting software changes or integrations from large extruder manufacturers is a slow, expensive, and bureaucratic process.

Because we develop our software in-house, we are often the “fast and easy” solution. If a customer needs a specific handshake protocol or a unique display feature, we can implement it in a fraction of the time it takes the giants of the industry. We adapt to the extruder, rather than forcing the extruder to adapt to us.

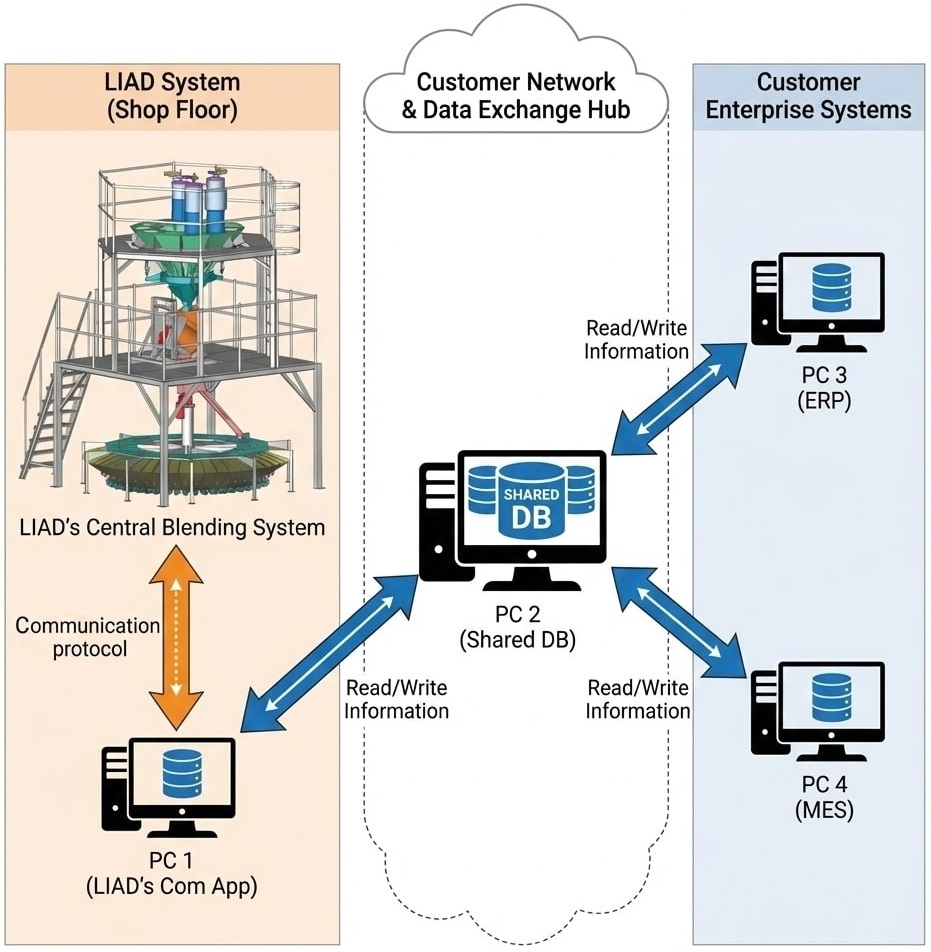

For our central blending systems, like PelletSave and BlendSave, integration is almost standard in large-scale projects. Today’s factories need to track every gram of material, and that requires speaking directly to the factory’s ERP or MES.

We typically handle this via database communication. We create a shared data environment by inserting production data into tables that the customer’s system reads or pulling recipe data directly from their servers.

A recent success story from a customer in the USA highlights this capability. They had a central dosing system coupled with a raw material loading system. We bridged their loading mechanism and our database. Now, when an operator loads a material bag, the data flows instantly to our system. We track exactly how much was loaded, how much was consumed, and how much remains. This provides the plant manager with real-time, automated inventory management, eliminating manual counting and paperwork.

Communication between the central blending system and the ERP and MES

Our connectivity extends to Quality Control as well. With the Spectro 4.0, we offer various integration methods to sync with a customer’s color data ecosystem. Furthermore, we don’t just look upstream; we look downstream. We have implemented simple yet effective I/O communication with end-of-line equipment, such as robots, ensuring that the entire line, from dosing to material handling, operates in sync.

Communication between the Spectro and third parties

If there is one thing we have learned, it is that no two factories are identical. Every customer has their own infrastructure, their own preferred protocols, and their own unique requirements.

This is where our strength lies. We do all our programming and development in-house. We do not force you into a rigid, “out-of-the-box” connectivity standard. Whether you need to exchange data via Modbus TCP/IP (standard on our ColorSave 1000) or through shared database tables (SQL) where we write data and your system reads it, we adapt to you.

We approach integration with a flexible mindset. If a customer wants to manage recipes through a specific database structure or pull production reports in a specific format, our engineering team builds that interface. We believe the machine should fit the factory, not the other way around.

Speak directly with our engineers and find ways to reduce cost, inventory and time

Request a Demo© Copyright Ampacet Corporation. All Rights Reserved