ColorSave® 1000X gravimetric feeder elevates operating efficiency with the ultimate in self-cleaning with patented SmartClean technology, unmatched dosing precision, and enhanced user experience.

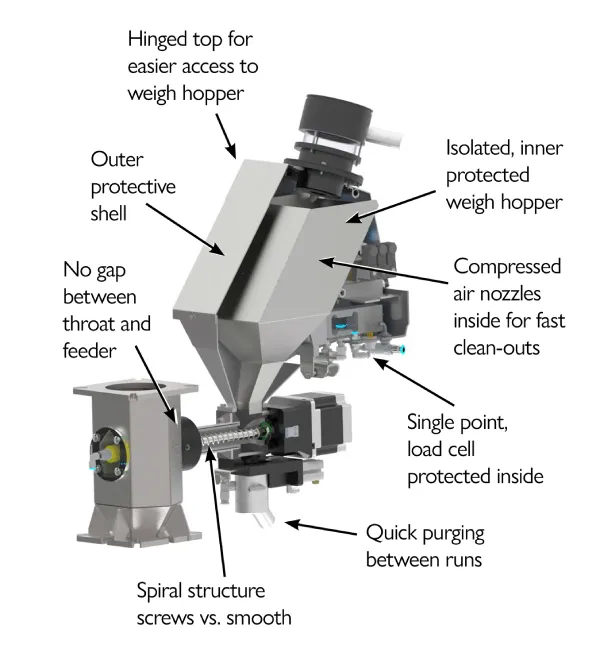

The ColorSave 1000X, featuring advanced SmartClean technology, now incorporates additional compressed air nozzles in the weigh hopper, efficiently expelling fines and dusty colorant. SmartClean technology purges colorant in 10 seconds, returning residuals to the storage container to save labor and production time while eliminating expensive color waste. Compatible with injection molding, extrusion, and blow-molding machines, ColorSave 1000X integrates with LIAD Smart Spectro™ for real-time color management.

The new ColorSave 1000X also includes an ergonomically designed PLC controller with a 7-inch touchscreen for improved usability and flexible mounting.

The hinged lid provides easy access to the weigh hopper, streamlining maintenance. The feeder stores up to 500 recipes, features an easy-to-replace feeding screw, and offers an optional integrated Venturi vacuum loader. Real-time data collection via control software provides production run material usage and rates.

ColorSave 1000X features an outer protective shell with an inner floating weigh hopper and a single-point load cell for accuracy in industrial settings with vibration.

ColorSave 1000X advanced algorithms ensure precise dosing despite material density changes, allowing manufacturers to feed expensive colors and additives at the lowest possible (LDR), reducing masterbatch costs.

ColorSave 1000X brings significant cost reductions when compared to standard volumetric feeders or batch blenders. Save up to 50% of your masterbatch (MB) costs by making the switch to the gravimetric ColorSave 1000X.

| ALTERNATIVE TECHNOLOGIES | MB SAVINGS WITH COLORSAVE 1000X |

| VOLUMETRIC FEEDER | Up to 50% |

| REMOTE BATCH BLENDER | Up to 35% |

| MACHINE THROAT BATCH BLENDER | Up to 15% |

ColorSave 1000X offers more advantages for your production than any other gravimetric or volumetric feeder.

| HOPPER | 3/5/10 Liter |

| OUTPUT RANGE | 0.2-100 kg/h (in volumetric mode 0.02-200 kg/h) |

| MOTOR | Powerful step motor |

| CONTROLLER | Sophisticated powerful PLC & HMI color touch screen all-in-one unit |

| COMMUNICATION | Modbus TCP/IP |

| LOAD CELL | 15 kg max., temp. compensated |

| LOADER | Automatic integral venturi vacuum loader |

| MOUNTING AND FEEDING | By neckpiece adapter, directly into the machine throat |

| ALARM OUTPUT | N/O or N/C dry contact 0V, optional 24V/30mA max |

| WEIGHT | 16 kg |

| POWER | 100-240v, 200W, 50/60hz |

Need a little extra to get the job done? Check out our accessories. Find one that makes your project that much easier.

Speak directly with our engineers and find ways to reduce cost, inventory and time

Request a Demo© Copyright Ampacet Corporation. All Rights Reserved