In the ever-evolving landscape of the nonwovens industry, precision and efficiency are no longer optional, they’re vital. We were happy to have the chance to help in transforming production lines into smart, data-driven environments where feeding accuracy is guaranteed.

One of our recent success stories comes from Latin America, where a leading nonwovens manufacturer faced new challenges in a rapidly shifting market. Armed with decades of experience and a bold investment in cutting-edge equipment, the company turned to us for a solution that would maximize its potential. What followed is a model of how gravimetric dosing and smart control can unlock dramatic improvements in cost-efficiency, product quality, and operational insight.

The Argentinean manufacturer, serving over 80 sectors and producing 12,000 tons annually, had recently installed a highly advanced production line for polypropylene-based nonwovens, with a 4,000-ton annual capacity. But while the new line offered speed and versatility, the company’s legacy volumetric dosing systems were struggling to keep up. Inconsistencies in coloring, formula inaccuracies, and waste were eating into profits. Meanwhile, customer demands were becoming stricter, and some long-time clients were launching in-house production, shrinking available market share.

To stay ahead, this leading player needed a smarter way to manage raw material dosing – particularly for masterbatch and fillers. That’s where LIAD stepped in.

Nonwoven material

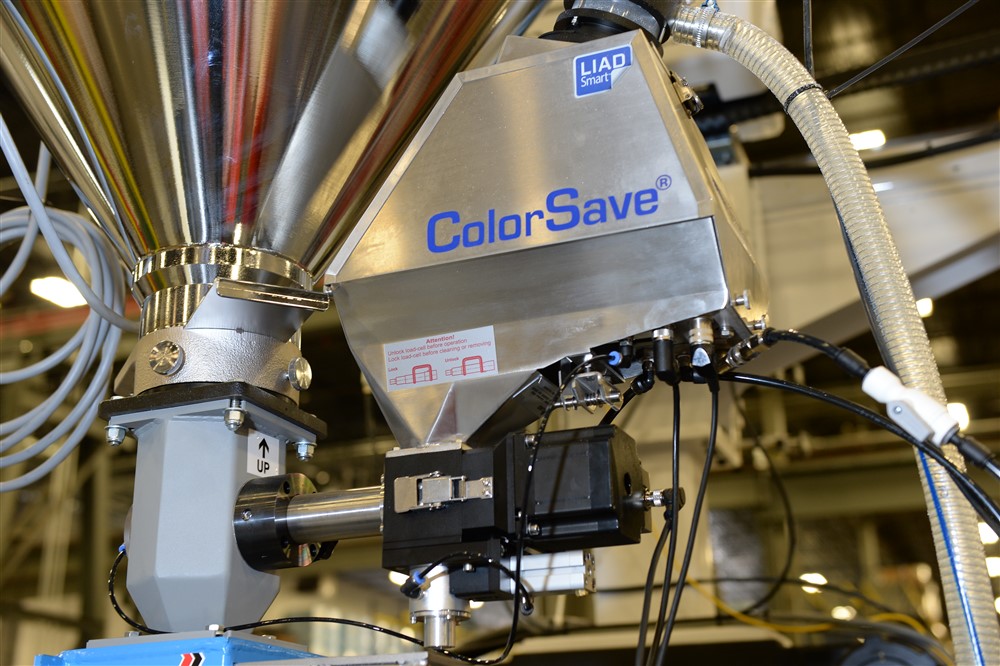

Our patented ColorSave 1000 gravimetric feeder was the ideal answer to the manufacturer’s needs. Together with our partners at Plast Sur, our official distributor in Argentina, we worked hand-in-hand with the client’s engineering team to seamlessly integrate the system.

This wasn’t just a plug-and-play fix. Our collaboration included mechanical adaptations, electrical connections, and full integration with the line’s centralized control panel.

The shift from volumetric to gravimetric dosing was a game-changer. Real-time, continuous measurement of masterbatch consumption gave the production team something they never had before: true visibility and control over their formulations. No more estimating. No more inconsistencies. Just accurate, optimized dosing, batch after batch.

The benefits were immediate and far-reaching:

With 27 colors now precisely managed and consistent quality delivered regardless of operator or shift, the manufacturer has positioned itself as a top-tier supplier in a demanding market.

ColorSave 1000

This case highlights more than a single installation. It’s a blueprint for the future of nonwovens and beyond. We believe that data-driven dosing is the foundation of modern plastics manufacturing. It leads to better decisions, tighter control, and products that meet the highest standards with maximum efficiency.

As global markets continue to evolve, we are committed to leading this transformation, empowering manufacturers with smart solutions to streamline their manufacturing and make it considerably more efficient.

Speak directly with our engineers and find ways to reduce cost, inventory and time

Request a Demo© Copyright Ampacet Corporation. All Rights Reserved