The plastics industry has witnessed a significant shift in recent years, with manufacturers increasingly incorporating recycled materials into their production processes. This trend is driven by a combination of factors, including stricter regulatory requirements, growing public demand for sustainable products, and the industry’s collective effort to reduce plastic waste.

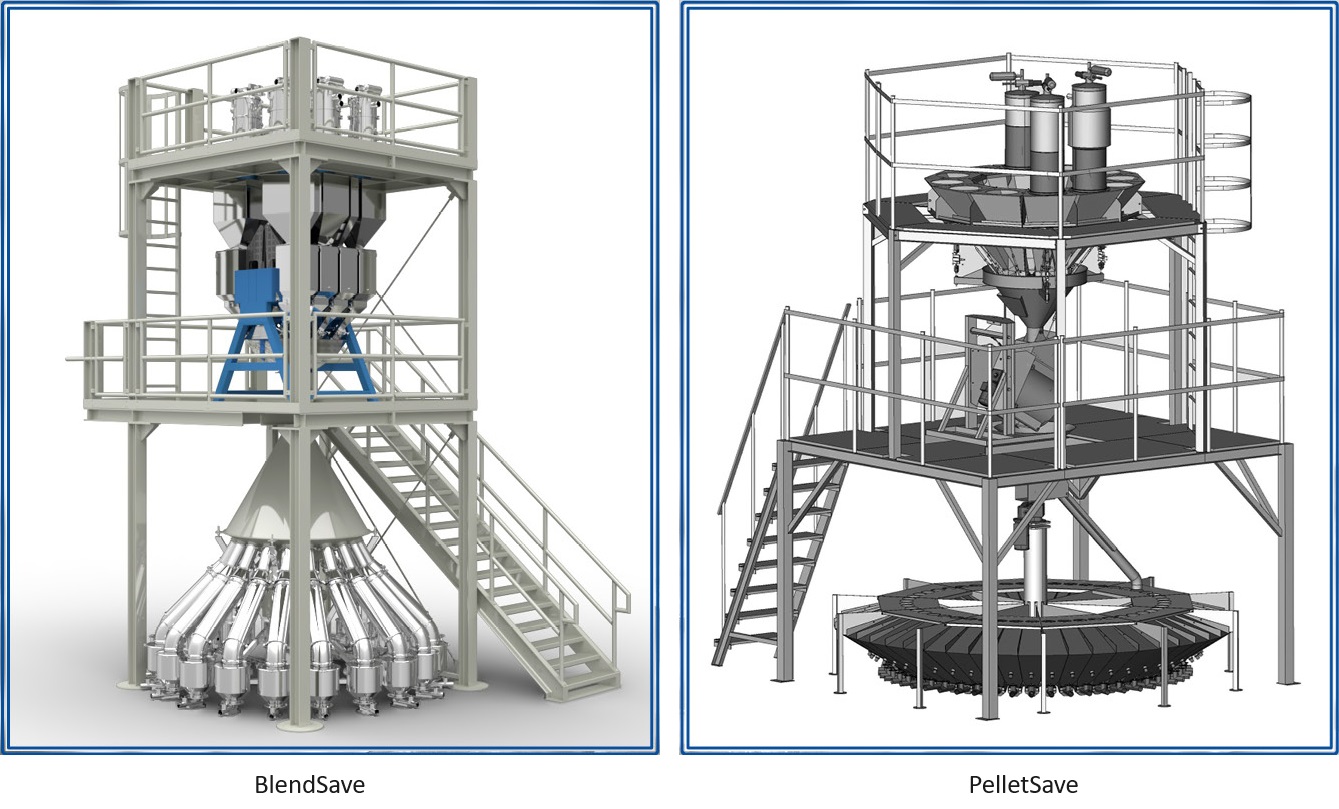

As manufacturers strive to meet these evolving market and environmental needs, they face the challenge of managing the diverse properties of recycled raw materials. To address this growing complexity, we, at LIAD, can offer two advanced central blending systems: PelletSave and BlendSave.

The increased use of recycled plastics in industrial applications is a direct response to the pressing need to protect the environment and reduce carbon footprints. However, the diverse nature of recycled materials poses a unique challenge for manufacturers.

Recycled plastics often exhibit a wide range of properties due to the complexities involved in the sorting and collection process. Improperly sorted or contaminated recycled materials, particularly clear plastics, can significantly impact the quality and consistency of the final product.

These inconsistencies force manufacturers to blend a large number of materials and additives to meet the product’s specifications and overcome the challenges of recycled materials. Thus, plastics manufacturers require advanced blending solutions that can effectively manage the growing variety of raw materials.

The PelletSave and BlendSave systems are designed to address the challenges posed by this evolving landscape. These advanced systems offer a range of benefits, including the ability to easily change recipes directly from the manufacturing execution system (MES), prevent human error, and maintain exceptional batch uniformity.

PelletSave, a cost-effective central blender, can weigh up to 18 ingredients in each mixture. The blending process is performed serially through one weighing channel.

BlendSave, a modular and highly flexible central blending system, can handle up to 50 ingredients. It employs up to 10 dedicated weighing chambers in one module, to ensure accurate and consistent weighing of raw materials. Integrating up to 5 modules and reaching a maximum of 50 weighing channels is possible. With its multiple and separate modules, BlendSave can perform parallel blending. This eradicates the risk of cross-contamination, a common challenge when working with recycled plastics and various types of raw materials.

Both systems are designed with Industry 4.0 principles in mind, enabling seamless integration with factory ERP systems. This allows for comprehensive monitoring and control of customized job status, batch blending, historical graphs, and performance reports, allowing manufacturers to make informed decisions and maintain optimal efficiency.

Switching between different material compositions is made effortless by the flexible recipe handling capabilities of PelletSave and BlendSave. Materials can be easily omitted from or introduced to the blend with just a few simple adjustments. The use of vacuum transfer ensures smooth, controlled movement of the various raw materials into the weighing chambers. This automated transfer eliminates the need for manual material handling. Cleaning is also streamlined through the use of high-pressure air blasts to clean the common funnel and distributor pipe between batches. This efficient cleaning process minimizes downtime and nearly eliminates the requirement for extensive manual cleaning intervention. The combination of flexible recipe control, automated vacuum transfer, and efficient self-cleaning capabilities allows for fast, hassle-free transitions between diverse material blends in both the PelletSave and BlendSave systems.

As the plastics industry continues to evolve, with manufacturers increasingly leveraging recycled materials, the need for advanced blending solutions has become paramount. Our central blending systems offer a comprehensive answer to this challenge, providing versatile, efficient, and highly accurate blending capabilities that empower manufacturers to navigate the complexities of modern plastic production. By embracing these innovative solutions, plastics manufacturers can optimize their material flow, maintain consistent product quality, and stay ahead of the curve in an ever-changing industry.

Speak directly with our engineers and find ways to reduce cost, inventory and time

Request a Demo© Copyright Ampacet Corporation. All Rights Reserved